From time to time a businesses’ outcomes will change as its purpose, linked to market forces, efficiency and capability considerations, also changes. Business purpose and leadership behavior manifest as the businesses’ overarching system and network of supporting sub-systems and standards. These, together with need, drive workplace ‘routines’ behavior and work practices. Should change in purpose extend to change in system, expectation thereafter is for a smooth rollout of (new) system to impact ‘routines’ behavior and work practice in each aspect of the businesses’ operation. But in every rollout, always outstanding is the question: will correctly designed and applied system change prove sufficient to actually cause desired change both in stakeholder ‘routines’ behavior and work practice, as and when required?

Change is easy when all of purpose, need, context and motives are understood by all stakeholders. Add but a hint of a self-serving motive or a less than timely and empathetic response to need and you can expect to fail. Expand motive to include the economic and social responsibilities of the business and the broader community of interest and need, and your chance of success dramatically improves. Change is constant and at an increasing rate. For business sustainability response to change is essential[1], for advantage anticipation of change fundamental. Success is ensured only to managerial leaders who demonstrate breadth of motive, respond with diligence to stakeholder need and provide them access to opportunity. Therefore, the answer to the outstanding question above is: it may not always be appropriate to depend on system alone to effect changes in ‘routines’ behavior and work practice, or to just build into the system’s design and rollout the features that should provide the impetus for the change, and expect these features to function exactly to specification. Rather managerial leaders must remain sensitive to the businesses’ broader economic and social environment, be alert to stakeholder needs, be open to opportunities to liberate human potential, and be ever ready to respond on an individual and collective basis, as required.

Implementation Considerations

Before embarking upon the implementation of any response to (or anticipation of) change in business purpose managerial leadership must decide:

- Does the appropriate reaction extend as far as the creation of new systems and/or amendment of existing systems?

- How to ensure the businesses’ systems align with both new purpose and need?

- How to define the change and make it inspirational at every level?

- How to respond in a timely manner to the explicit and implicit but constant question “what’s in it for me?”

- How to determine the foundation upon which to base the response that is exactly right for the future of the business and its stakeholders? (refer Figure 1).

- Once the required change (to system if necessary) is initiated, what will be the impact on stakeholder ‘routines’ behavior and work practice and how might change at this level best be managed, and finally,

- What action is required and what tools must be used to ensure the change will be implemented with the full commitment of each stakeholder at every level in an effective, efficient and timely manner?

Figure 1

‘Routines’ Behavior and Work Practices

If your need is for results that are different from what you are getting now, you will have to change the way you do things, and certainly you will need to inspire others to do likewise. For each stakeholder at every level this extends to ‘routines’ behaviors and work practices that might be new or different and therefore require specific system design features and stakeholder commitment to effect and sustain the change as follows:

- Ensuring a clear understanding of process

- Taking more issues into consideration and requiring more input, and more timely input, into scheduling and then planning decisions.

- Turning up on time to meetings.

- Making interaction about the schedule with managers and other departments routine.

- Providing more advance information to team members and stakeholders.

- Planning further ahead (perhaps 4 weeks instead of 1 day).

- Involving the team members / stakeholders who will be doing the work in planning the tasks (getting close, asking opinions, enabling the input of planning information, giving recognition and coaching to improve their personal contribution and effectiveness).

- Representing your peers at planning and scheduling meetings.

- Understanding completely and reacting appropriately to every team member and stakeholder’s point of work execution controlissues i.e. the work that is within their control and for which they are accountable.

- Being crystal clear about expected process and schedule outcomes, measures to be applied, timelines, costs and contingencies.

- Ensuring an understanding of what Key Performance Indicators (KPIs) are measuring and measuring yourself, your team members and stakeholders against work process targets.

- Being accountable for delivery of the schedule and specifying exactly who is accountable for what, by when.

Making the change without too much pain is much easier when the initiative (and/or system) both pulls for and supports each stakeholder’s new ‘routines’ behavior and work practice.

Making the Change Stick

When it comes to change there is a fundamental need to ensure:

- The engagement of stakeholders from the outset.

- Required standards are identified, developed, supported and maintained.

- Improvement are made exactly to schedule and standard.

- Change is permanent.

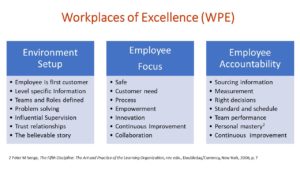

- Workplaces of excellence are a by-product of the change (refer Figure 2), and

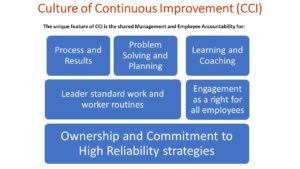

- A culture of Continuous Improvement is a natural evolution.

In embarking upon the process of change the focus must first be on the existing systems and business processes, subsidiary activities, tasks, and work method. The next step is to substantially involve the stakeholders and team members who do the work now and who will have the greatest involvement in any new order, and particularly understand the extent of their required point of work execution control and their need.

Thereafter, managers and supervisors can move on to the development and design of the system (and symbols) that will create the new order with consideration of opportunities to enable workforce / stakeholder contribution to new initiatives satisfying need. In this way, every spark of existing stakeholder commitment can be captured and strengthened and their personal investment in the new systems, business processes, activities, task methods and (new) ‘routines’ behavior and work practices ensured.

Following this process will lead to an increase in stakeholder task satisfaction, the creation of opportunity to liberate their potential and an increased sense of ownership in task outcomes and process performance. And don’t forget that every team member and stakeholder is also committed to seeing the business enjoy a prosperous future and will labor hard for its realization where the purpose, context and motive is clear, because they are depending upon that future success to satisfy their own needs.

Figure 2

[1] Consider that if the only constant is change then we will change, either through a reactionary process or by being the change, living the change, defining the change. Darwin would tell us that those that are apt to define the species in the future are those most adaptable to change. We might argue that a step beyond this is: those that define change, as opposed to adapting to it, are the future.